SS Series Blow Moulding machine for large bottle

BRIEF INTRODUCTION

Mega Machinerys’ SS Series automatic linear PET blow moulding machines was designed with two principles in mind. One, to lower the running cost for the bottle producer and two provide easy operation. The MG-SS Series PET blow moulding machines lowers your production costs so you can achieve maximum profits in your competitive bottling market, the blower reduces your energy expenses by up to 30% at a maximum output of 1500 bottle per cavity per hour. Thanks to our GM Mr. Cai Yuansen who developed the special mechanical designs which maximizes the performance of the machine.

Overview

*Precise controller

MG-SS series PET blow moulding machines adopts the famous Delta controller system. It integrates a self-diagnosis program, all warning information is shown through the friendly touch interface featuring an alarm system. Also, the controller shows the actual blowing speed during production.

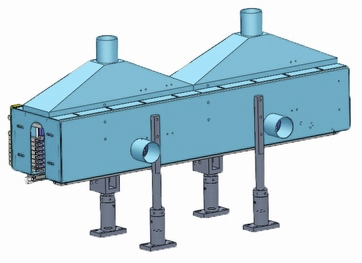

*Preform loading system

Famous brand pneumatic parts guarantee the machines reliable performance and long service life while Linear motion guides improve the moving speed. Special grip units are designed to be changed easily.

*Infrared heating system

A Zoned and layered heating system with an advanced venting unit keeps the temperature accurate and uniform, this is the key to manufacturing high quality plastic bottles. The lamps can also be adjusted horizontally and vertically inside the specially designed heating oven. This ensures the distribution of heat meets the different shapes of the preforms.

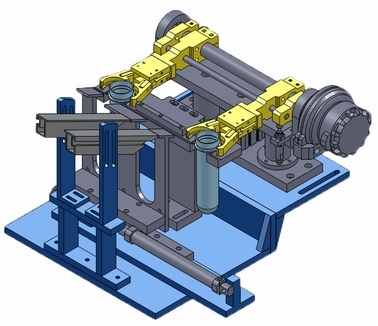

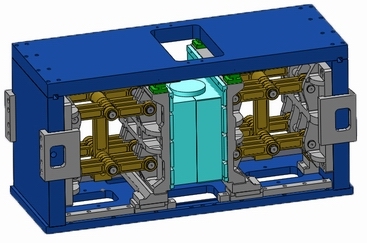

*Cast molded platen with toggle clamping unit

Cast molded platens offer the longest service life, and enhance the stability of the machine. Engineering software analyzed and optimized the clamping system to guaranty the fastest possible moving speed and strongest clamping force. Also an additional high pressure compensation system is standard equipment and ensures the perfect clamping result.

*Stretching system

A double cylinder stretching unit is standard equipment , It provided the fastest possible stretching speed, and the longest possible stretching stroke. Linear motion guides provide ultra smooth movement and the lowest possible friction coefficient.

Features

1. Special loading system carries the preform automatically with less moving parts.

2. Suitable to produce 5L ~20L Standard neck PET container

3. Advanced PLC control system with a use-friendly control panel

4. Built-in memory of the PLC saves all the sets of numbers required to produce different size bottles.

5. Multiple Reliable sensor systems monitors the machine’s automatic function

6. Equipped with special designed air storage unit

7. Powerful heating unit with precision controller and convenient adjusting mechanism.

8. Cooling system that provides a perfect cooling result

9. Compact design that saves space

10. Simple installation & start up operation

11. minimal transfer space for the air distribution system.

Bottle SamplesPET bottles produced by SS series automatic reheat PET stretch blow molding machine:

Specification

| General information | MG-SS2L | MG-SS2EL | MG-SS3L | MG-SS4L | MG-SS4EL |

|---|---|---|---|---|---|

| Clamping Force | 50T | 55T | 58T | 68T | 80T |

| Clamping Stroke | 200mm | 250mm | 220mm | 220mm | 250mm |

| Max. Stretching Stroke | 500mm | 550mm | 380mm | 380mm | 550mm |

| Bottom Moving Stroke | 70mm | 70mm | 70mm | 70mm | 70mm |

| Number of Cavities | 2 Cavity | 2 Cavity | 3 Cavity | 4 Cavity | 4 Cavity |

| Theoretical Output | 1600BPH | 1200BPH | 2500BPH | 3500 BPH | 2700BPH |

| Max. Mould Thickness | 290mm | 322mm | 300mm | 300mm | 322mm |

| Electrical System | |||||

| Voltage Standard | 380v/3PH/50Hz | or special order | |||

| Number of Heating Zone | 5 Sections | 7 Sections | 6 Sections | 8 Sections | 7 Sections |

| Total Power (Full Loaded) | 60KW | 80KW | 80KW | 100KW | 120KW |

| Container | |||||

| Max. Container Volume | 6L | 10L | 5L | 5L | 10L |

| Neck Diameter Range | 50mm | 50mm | 50mm | 50mm | 50mm |

| Max. Container Diameter | 190mm | 220mm | 190mm | 190mm | 220mm |

| Max. Container Height | 350mm | 400mm | 360mm | 360mm | 400mm |

| Air system | |||||

| Low Air consumption | 8-10Bar | 8-10Bar | 8-10Bar | 8-10Bar | 8-10Bar |

| High Air consumption | 30-35 Bar | 30-35 Bar | 30-35 Bar | 30-35 Bar | 30-35 Bar |

| Dimension & Weight | |||||

| Blow molding machine | 2.9×2.22×2.3m | 3.56x.22×2.3m | 4×2.15×2.2m | 4.2×2.15×2.2m | 5×2.2×2.3m |

| Preform Autoloader | 2.5×1.6×2.8m | 2.5×1.6×2.8m | 2×1.2×2.2m | 2×1.2×2.2mm | 2.5×1.8×2.8m |

| Net Weight | 5.5T | 6.5T | 7T | 8T | 10T |

| General information | MG-SS1EXL | MG-SS2EXL |

|---|---|---|

| Clamping Force | 500KN | 1050KN |

| Clamping Stroke | 330mm | 305mm |

| Max. Stretching Stroke | 550mm | 550mm |

| Bottom Moving Stroke | 60mm | 60mm |

| Number of Cavities | 1 cavity | 2 Cavity |

| Theoretical Output | 400BPH | 750BPH |

| Max. Mould Thickness | 420mm | 420mm |

| Electrical System | ||

| Voltage Standard | 380v/3PH/50Hz | or special order |

| Number of Heating Zone | 8 Sections | 8 Sections |

| Total Power (Full Loaded) | 45KW | 85KW |

| Container | ||

| Max. Container Volume | 5Gal | 5Gal |

| Neck Diameter Range | 70mm | 70mm |

| Max. Container Diameter | 280mm | 280mm |

| Max. Container Height | 535mm | 535mm |

| Air system | ||

| Low Air consumption | 8-10Bar | 8-10Bar |

| High Air consumption | 30-35 Bar | 30-35 Bar |

| Dimension & Weight | ||

| Blow molding machine | 4.8X2.15X1.6m | 5.8×2.2×1.9m |

| Preform Autoloader | _ _ | _ _ |

| Net Weight | 4T | 6T |

Mega Machinery, the Professional PET Blow Moulding Machine supplier in China.

Note: PET stretch blow molding machine is also known as Reheat stretch blow molding machines, Stretch blow molding machines, bottle blowing machine, blowing machines and PET blow molding machine.