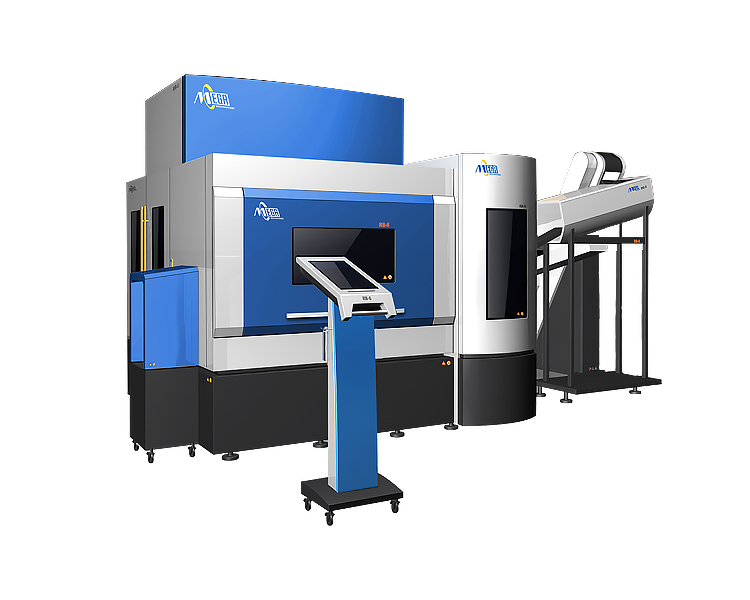

RB Series Rotary Blow Moulding Machines

Brief Introduction

RB Series is the latest Rotary Blow Moulding Machine from Mega Machinery. Our R&D team has dedicated to design the machine by principle of engineered efficiency. Compare to earlier generation, New RB series requires less power due to the small pitch at pre-heater. Thanks to the Optimized clamping unit, the NEW Rotary blow moulding machine has wider operation window. Improved new machine kinematics reach output rates at 1,800 bottles per hour per cavity for light weight 0.5L water application.

Overview

* Preform Feeding and Loading

The recycling unit keeps preforms from getting jammed in the unscrambler. The star wheel designed feeding unit, provides easy way of changeover time for different neck preform.

* Linear Oven

Turning 180℃ mandrel guarantee the uniform neck section even at critical heating oven. Super small pitch design consumes less power. Unique oven ventilation design make RB series Blow moulding machine handles various of difficult application easily.

* Preform and Bottle Transfer Wheel

Thanks to the classic designed double cam telescopic gripper system, it guarantees the reliability of the movement, and easy to maintain it.

* Moulds and Mould Carriers

The mould carriers adopts shell blow mould design, this reduces the changeover time for different blow moulds. The Mould carriers allow the use of all shell type of moulds form conventional rotary blow moulding machines; it saves the costs for bottle producer. The reliable and quick locking system maximizes the performance of the mould carriers.

* Blowing station

Changeable cam stretching curve guider guarantees the quality of different bottles. Monobloc blowing valves achieve the fastest and more consistent blowing process. Bottle neck is protected during the blowing by special designed sealing unit.

Option

* PID system for heating zone (Option)

Infrared thermometer automatic detect the temperature of performs, adjust the temperature of oven automatic. It avoids the influence of temperature different between day time and night. Also the system can add additional lamp alarm unit, It alarms when detected any broken lamps or aging lamps.

* Special Air Recovery system (Option)

We know the most production cost for blowing the bottles is from generating the high pressure compressed air and reheating the preforms, In order to reduce the production cost for the bottler producer, Mega has introduced Air recovery system. This system recovers up to 30% of final high pressure blowing air.

* Air cooling system (Option)

Thanks to our GM Cai Yuansen, we have developed air cooling system for hot fill PET bottles, after high pressure blowing, an air cooling is introduced it to reduce the level of PET residual stress, and increase the rate of PET crystallization . After air cooling process, PET bottle could stand hot fill without deformation.

Container/Bottle Samples

PET bottles produced by RB Series Rotary Blow Moulding Machines:

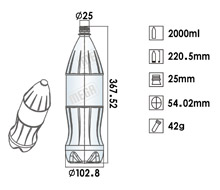

2L CSD bottle

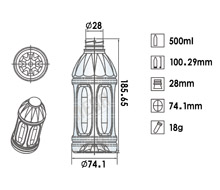

500ml hot fill PET bottle

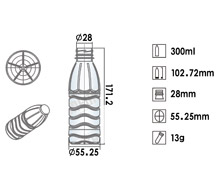

300ml water bottle

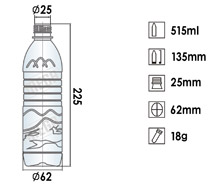

515ml water bottle

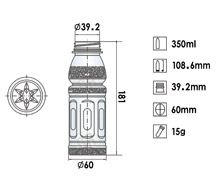

350ml hot fill PET Bottle

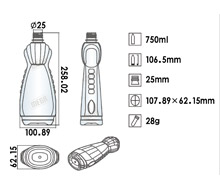

750ml detergen bottle

Specification

| Type | RB4 | RB6 | RB12 | RB16 |

|---|---|---|---|---|

| Production output | ||||

| Per cavity | 1,300 BPH | 1,400 BPH | 1,800 BPH | 1,800 BPH |

| Machine output | 5,200 BPH | 8,400 BPH | 21,600 BPH | 28,800 BPH |

| Bottle dimensions | ||||

| Max. volume | 2 L | 2 L | 3 L | 3 L |

| Min. volume | 0.1 L | 0.1 L | 0.1 L | 0.1 L |

| Max. diameter | 110 mm | 110 mm | 115 mm | 115 mm |

| Max. height | 300 mm | 300 mm | 350 mm | 350 mm |

| Preform dimensions | ||||

| Preform neck | Up to 42 mm | Up to 42 mm | Up to 32 mm | Up to 32 mm |

| Preform support ring | Up to 48 mm | Up to 48 mm | Up to 36 mm | Up to 36 mm |

| Machine dimension | ||||

| Blower Floor space (LxWxH) | 2.4×1.7×3.0 (M) | 2.0×2.7×3.0 (M) | 2. 5 x3.0x3.2 (M) | 2.8×3.3×3.2 (M) |

| Oven Floor space (LxWxH) | 3.0×0.9×3.0 (M) | 3.4×0.8×2.4 (M) | 5.0×1.5×2.0 (M) | 5.5×1.5×2.0 (M) |

| Electrical supply | ||||

| Voltage standard | 380V/3PH/50HZ | or Special order | ||

| Power (Max load) | 90KW | 120KW | 220KW | 260KW |

| Air supply | ||||

| Max. blowing | 40 Bar | 40 Bar | 40 Bar | 40 Bar |

| Pressure | 580.15 PSI | 580.15 PSI | 580.15 PSI | 580.15 PSI |

| Air consumption | 3. 5 M 3 /Min | 6.0 M 3 /Min | 15 M 3 /Min | 20 M 3 /Min |

| Cooled water supply | ||||

| Water pressure | 4 Bar | 4 Bar | 4 Bar | 4 Bar |

| Water pressure | 58 PSI | 58 PSI | 58 PSI | 58 PSI |

| Water temperature | 10 ℃ | 10 ℃ | 10 ℃ | 10 ℃ |

| Water temperature | 50 ? | 50 ? | 50 ? | 50 ? |

Mega Machinery, the Professional High speed rotary blow moulding machine supplier in China.

Note: Rotary blow moulding machine is also known as Rotary PET stretch blow molding machine, Rotary pet blow moulding machine, Rotary bottle blowing machine.