MG-S Series Extrusion Blow Moulding Machine (Single station)

Brief Introduction

The MG-S series is single station extrusion blow moulding machine for containers from 5ml up to 18L, their high level of reliability, excellent efficiency and flexibility to meet varied customer requirements. The MG-S series process a variety of materials, including HDPE, LDPE, PP, PVC, TPU, PETG and other materials. The MG-S extrusion blow moulding machine cover the complete production scope starting from the smallest ampoule or tube to beverage packaging, cosmetic containers, large mouth containers and multiple layers with view stripe line containers, large mouth containers and multiple layers with view stripe line containers.

MG-S extrusion blow moulding machine’s Options

- Parison thickness controller

- View stripe heads

- Wide mouth Jar trimmer

- Multi head capability

- Automatic deflashing

- Leak tester at bottle outlet

- In-Mould-Labeling

- Co-extrusion

Container/Bottle samplesContainer produced by MG-S Series Extrusion Blow Moulding Machine:

1.5L container

Industrial container

Portable water dispenser

20L Industrial container

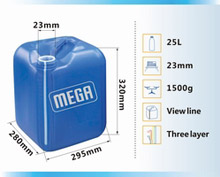

Multiple layer Industrial container

Blow molded Toy

Gear oil container with view stripe

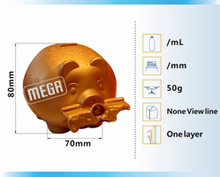

Piggy bank

Watering pot

Technical Parameter

| Model | MG-S2L | MG-S5L | MG-S12L | MG-S18L | |

|---|---|---|---|---|---|

| Materials | PE, PP… | PE, PP… | PE, PP… | PE, PP… | |

| Number of Head | Set | 1, 2, 3, 4, 6 | 1, 2, 3 | 1, 2 | 1, 2 |

| Theoretical Output | Pcs/h | 1400 | 1000 | 800 | 700 |

| (L×W×H) Dimension | M | 2.5×1.6×2.4 | 2.9×1.85×2.65 | 3.8×2.3×3.1 | 4.8×3.2×3.1 |

| Max Container | L | 2 | 5 | 12 | 18 |

| Weight | T | 3 | 4.5 | 6 | 7.8 |

| Extrusion Head | |||||

|---|---|---|---|---|---|

| Heating Zone | Zone | 3 | 3 | 3 | 3-4 |

| Heating Capacity | KW | 4 | 5.8 | 6-7 | 6-9 |

| Single head Product Max height | MM | 220 | 230 | 275 | 350 |

| Single head Product Max dia. | MM | 155 | 300 | 210 | 300 |

| Double head Max height | MM | 220 | 200 | 275 | 250 |

| Double head Product Max dia. and center distance | MM | 95, 130 | 180, 160 | 105, 240 | 190, 240 |

| Double head Max height | MM | 220 | 220 | ||

| Double head Product Max dia. and center distance | MM | 65, 85 | 85, 110 | ||

| Triple head Max height | MM | 120 | 200 | ||

| Triple head Product Max dia. and center distance | MM | 65, 60 | 70, 80 | ||

| Sextuple head Max height | MM | 120 | 200 | ||

| Sextuple head Product Max dia. and center distance | MM | 20, 60 | 30, 80 |

| Clamping unit | |||||

|---|---|---|---|---|---|

| Clamping force | KN | 60 | 60 | 110 | 110 |

| Toggle Stroke | MM | 138~368 | 148~508 | 240~620 | 1240~620 |

| (W×H) Mold Platen | MM | 300×320 | 370×390 | 530×510 | 530×510 |

| Mold Height | MM | 138~210 | 155~300 | 245~380 | 235~380 |

| Power | |||||

|---|---|---|---|---|---|

| Pump Drive | KW | 7.5 | 7.5 | 11 | 11 |

| Screw Drive | KW | 11 | 15 | 22 | 30 |

| Screw Fan | KW | 0.25 | 0.25 | 0.25 | 0.3 |

| Blow Pressure | MPA | 0.6 | 0.6 | 0.6 | 0.6 |

| Air consumption | M3/MIN | 0.4 | 0.4 | 0.8 | 0.8 |

| Max Load | KW | 28 | 33 | 42 | 55 |

| Plasticizing | |||||

|---|---|---|---|---|---|

| Screw Diameter | MM | 50 | 60 | 70 | 80 |

| Screw L/D | L/D | 24:1 | 24:1 | 24:1 | 24:1 |

| Extrusion Capacity | KG/H | 30~50 | 65~80 | 100~120 | 130~160 |

| Heating Zone | ZONE | 3 | 3 | 3 | 4 |

| Heating Capacity | KW | 4.5 | 6.6 | 8.2 | 9 |

All specifications and designs are subject to change without note.

Mega Machinery, the Professional extrusion blow moulding machine equipment supplier in China.

Note: Extrusion blow moulding machine is also called as extrusion blow molding machine.