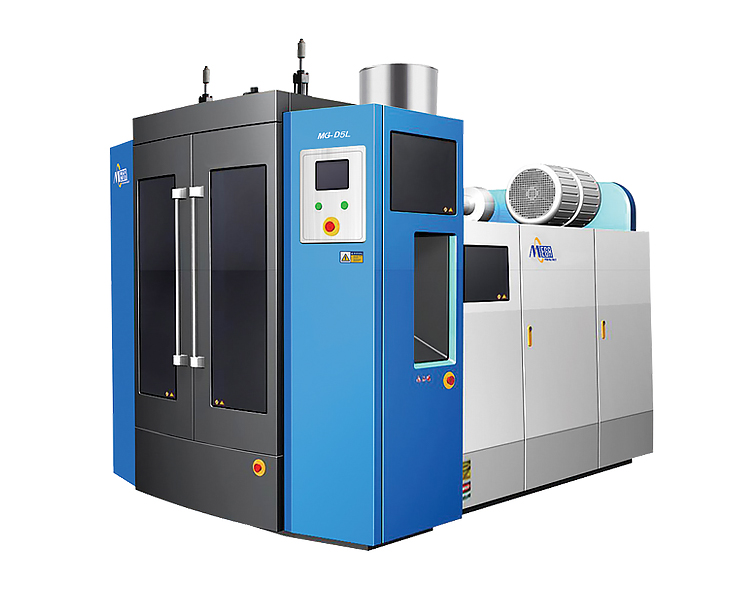

MG-D Series Extrusion Blow Moulding Machine (Double station)

Brief Introduction

The MG-D series is double station extrusion blow moulding machine for containers from 5ml up to 18L, Its high level of reliability, excellent efficiency and flexibility to meet varied customer requirements. MG-D extrusion blow moulding machines process a variety of materials, including HDPE, LDPE, PP, PVC, TPU, PETG and other materials. Compare to the S series extrusion blow moulding machine, The D type of machine has faster production rate in an hour. MG-D series machine cover the complete production scope starting from the smallest ampoule or tube to beverage packaging, cosmetic containers, large mouth containers and multiple layers with view stripe line containers.

MG-D Extrusion Blow Moulding Machines Options

- Parison thickness controller

- View stripe heads

- Wide mouth Jar trimmer

- Multi head capability

- Automatic deflashing

- Leak tester at bottle outlet

- In-Mould-Labeling

- Co-extrusion

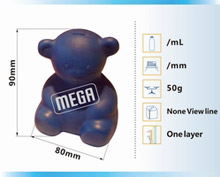

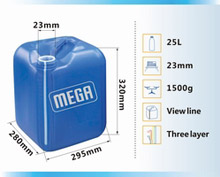

Container/Bottle samplesBottles produced by MG-D Series Extrusion Blow Moulding Machines:

5L Gear oil container

20L Industrial container

Toy bank

5L Lubrication oil container

25L Industrial container with view stripe

Toy

Two layer 10L Industrial container

Lubrication oil container

Watering pot

Technical Parameter

| Model | MG-D2L | MG-D5L | MG-D12L | MG-D18L | |

|---|---|---|---|---|---|

| Materials | PE, PP… | PE, PP… | PE, PP… | PE, PP… | |

| Number of Head | Set | 1, 2, 3, 4 | 1, 2, 3, 4 | 1, 2 | 1, 2 |

| Theoretical Output | Pcs/h | 900×2 | 700×2 | 700×2 | 800×2 |

| (L×W×H) Dimension | M | 2.9×2.1×2.6 | 3.6×2.3×2.6 | 4.1×2.9×3.1 | 4.9×4.2×3.1 |

| Max container | L | 2 | 5 | 12 | 18 |

| Weight | T | 4.2 | 7.8 | 10.8 | 13.8 |

| Extrusion Head | ||||||

|---|---|---|---|---|---|---|

| Heating Zone | Zone | 3 | 3 | 3 | 3-4 | |

| Heating Capacity | KW | 4 | 5.8 | 6-7 | 6-9 | |

| Single head | Product Max height | MM | 220 | 230 | 275 | 350 |

| Product Max dia. | MM | 155 | 300 | 210 | 300 | |

| Double head | Max height | MM | 220 | 200 | 275 | 250 |

| Product Max dia. and center distance | MM | 95, 130 | 180, 160 | 105, 240 | 190, 240 | |

| Triple head | Product Max height | MM | 220 | 220 | ||

| Product Max dia. and center distance | MM | 65, 85 | 85, 110 | |||

| Quadruple head | Product Max height | MM | 120 | 220 | ||

| Product Max dia. and center distance | MM | 65, 60 | 70, 80 | |||

| Sextuple head | Product Max height | MM | 120 | 200 | ||

| Product Max dia. and center distance | MM | 20, 60 | 30, 80 |

| Clamping unit | |||||

|---|---|---|---|---|---|

| Clamping force | KN | 60 | 60 | 110 | 110 |

| Toggle Stroke | MM | 138~368 | 148~508 | 240~620 | 1240~620 |

| (W×H) Mold Platen | MM | 300×320 | 370×390 | 530×510 | 530×510 |

| Mold Height | MM | 138~210 | 155~300 | 245~380 | 235~380 |

| Power | |||||

|---|---|---|---|---|---|

| Pump Drive | KW | 7.5 | 7.5 | 15 | 15 |

| Screw Drive | KW | 11 | 15 | 22 | 30 |

| Screw Fan | KW | 0.25 | 0.25 | 0.25 | 0.3 |

| Blow Pressure | MPA | 0.6 | 0.6 | 0.6 | 0.6 |

| Air consumption | M3/MIN | 0.4 | 0.4 | 0.8 | 0.8 |

| Max Load | KW | 28 | 33 | 46 | 60 |

| Plasticizing | |||||

|---|---|---|---|---|---|

| Screw Diameter | MM | 50 | 60 | 90 | 90 |

| Screw L/D | L/D | 24:1 | 24:1 | 24:1 | 24:1 |

| Extrusion Capacity | KG/H | 30~50 | 65~80 | 100~120 | 130~160 |

| Heating Zone | ZONE | 3 | 3 | 3 | 4 |

| Heating Capacity | KW | 4.5 | 6.6 | 8.2 | 9 |

All specifications and designs are subject to change without note.

Mega Machinery, the Professional manufacturer for extrusion blow moulding equipments in China.

Note: Extrusion blow molding machine is also called as extrusion blow moulding machine and blow molding machine.